Zinkflake Plants - Topcoat - Other Plants

Caber Impianti srl has been manufacturing for 30 years fully automatic and semi-automatic DACROMET and GEOMET plants with production outputs from 500 to 3000 kgs per hour applying two coats.

Geomet treatment plant for treating 3000 kgs per hour of small metal parts including Plus final coat.

Dacromet treatment plant for 1000 kgs per hour applying two coats.

Special booth for double washing to clean big bearings during overhaulling phase.

Treatment capacity: n.. 16 bearings each cycle, complete of cartridge filter and liquid stocking tanks. Treatment cycle: Degreasing - Rinsing - Drying - Oiling - Final Cooling

Plants working in Italy and Great Britain.

Washing and rinsing booth for dies coming from production.

Max. dim. Of dies to be cleaned: 3200 x 1500 x h 700 mm

The booth is working in France, Usa and Slovenja

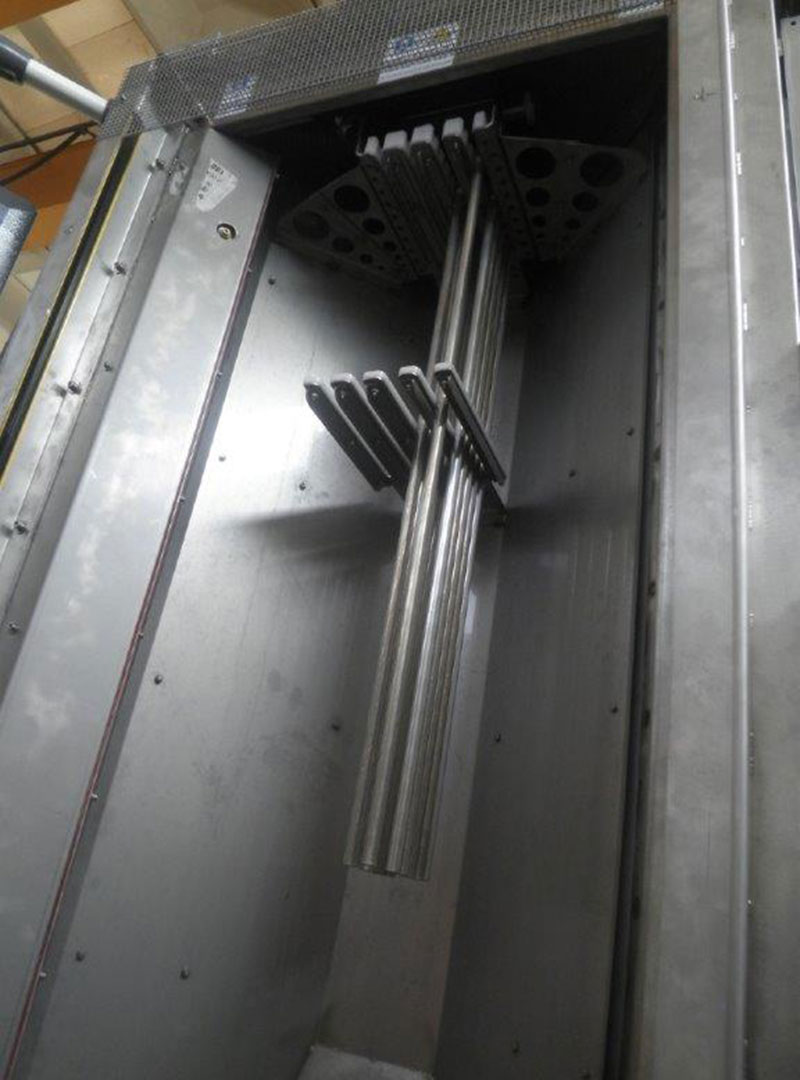

Washing and blowing booth for steering shafts

After thermical and quenching treatment.

The booth, performed in AISI 304, is working in Germany.

Washing machine on rotating table for cooling-pipes cleaning – automotive field.

Cycle: washing - rinsing - drying Capacity: 40 pcs/5'. L. pipes: 100-2000 mm

Plants working in France, Poland and Portugal

Process line for DACROFORGE fully automatic having a throughput capacity of 2000 Kgs per hour.

This process line is the first in the world for lubricating parts before cold stamping.

Process Plant for the application of DRD technology incorporating a curing furnace at 180°C for Dacrolube/Plus.

PLUS APPLICATION PLANT

Treatment capacity: 2000 kg/h.

Special washing machine on rotating table.

Performed for treatment of n. 5 collectors of common rail system, complete of filtering 100 micron. Cycle: washing - blowing - drying

Plant functioning in France.